Automation & Smart Manufacturing

Driving Efficiency Through Integrated Systems

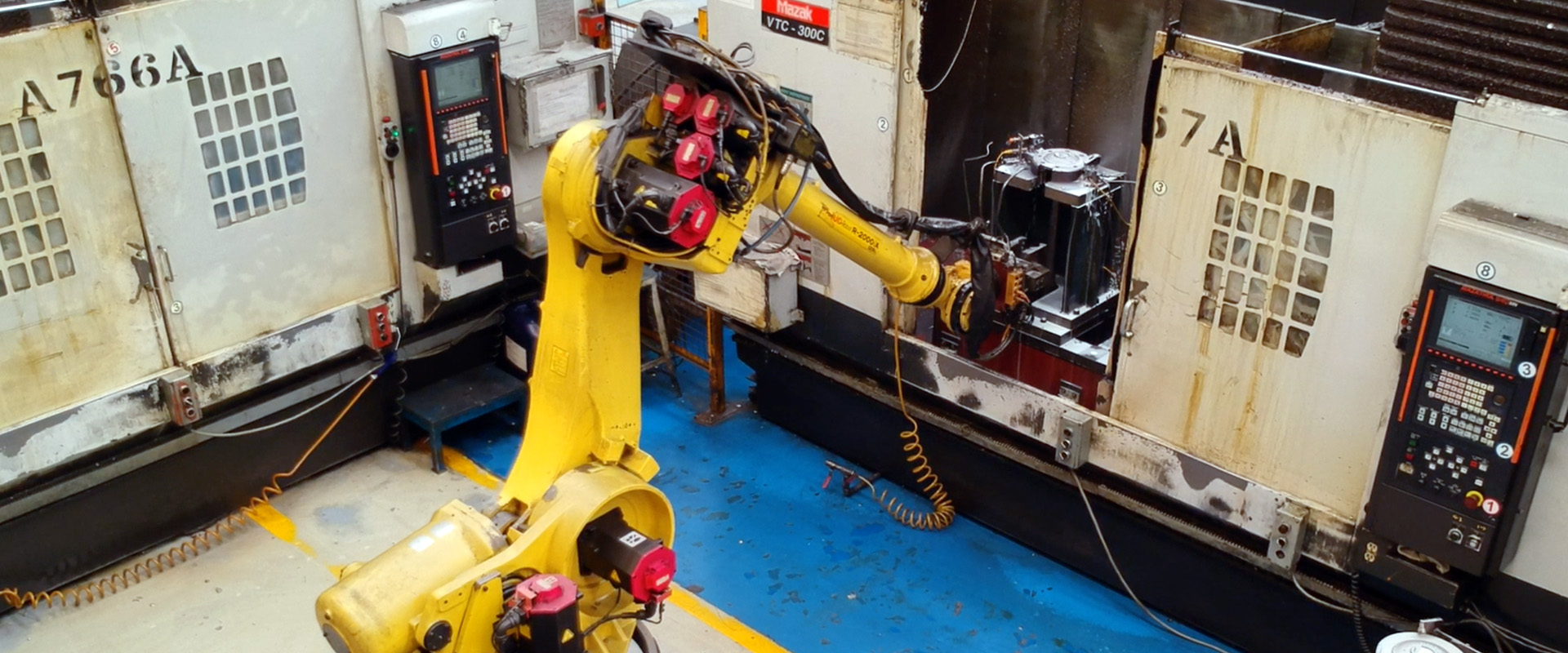

Automation & Smart Manufacturing at Sypris Technologies

Sypris Technologies integrates advanced automation and data-driven manufacturing systems to drive process stability, throughput efficiency, and part quality across all production disciplines. Our investment in smart manufacturing technologies enables repeatable execution, reduced cycle times, and real-time performance monitoring at both the equipment and enterprise levels.

We apply automation strategically across forging, machining, welding, heat treating, and assembly operations; not as isolated technologies, but as a fully integrated production ecosystem.

Intelligent Automation Architecture

Our automation infrastructure is designed for flexibility and scalability. From robotic work cells to data-rich PLC networks, we configure systems that support both high-volume production and mixed-model manufacturing environments.

Automation platforms include:

- Robotic Cells: Multi-axis robots for material handling, welding, and machine tending

- CNC Machine Integration: Automated part loading/unloading with vision systems and tool condition monitoring

- Programmable Logic Controllers (PLCs): Custom ladder logic and HMI interfaces for real-time control

- Palletized Transfer Systems: For sequenced flow between machining, inspection, and assembly stages

- Error-Proofing (Poka-Yoke): Sensors, interlocks, and feedback loops to prevent human or process errors

Smart Manufacturing Systems

We have implemented enterprise-wide digital systems to enable data capture, process analytics, and predictive response across the production lifecycle. These tools support decision-making at the operator, engineer, and executive levels.

Digital manufacturing capabilities:

- MES (Manufacturing Execution Systems): Real-time production tracking, work order control, and route enforcement

- SCADA Systems: Supervisory control of process data, alarms, and energy usage

- SPC Integration: Continuous quality monitoring tied to upper/lower control limits and live corrective action triggers

- Predictive Maintenance: Vibration, thermal, and cycle count analysis to prevent unplanned downtime

- Digital Dashboards: Live KPIs for OEE, scrap, downtime, and cycle adherence across departments

Use Case Applications

Automation is deployed where it yields maximum operational impact; enhancing safety, repeatability, and capacity while reducing labor variation and rework.

Integrated automation use cases:

- Robotic welding with seam tracking and adaptive arc parameters

- CNC machining with automated gauging and in-process inspection

- Forging line billet feeding and part ejection systems

- Heat treat batch loading with barcode-driven recipe selection

- Torque control and vision validation in assembly cells

Continuous Improvement Through Automation

Automation is a core enabler of our Lean and Six Sigma initiatives. It supports standard work, error reduction, takt time alignment, and defect prevention; all critical to our culture of continuous improvement.

Methodologies enhanced by automation:

- 5S + Visual Controls: Automated alerts and displays

- Kaizen Events: Focused automation upgrades based on bottleneck analysis

- TPM (Total Productive Maintenance): Autonomous maintenance alerts and diagnostics

- SMED (Single-Minute Exchange of Dies): Automated tooling and part setup transitions

Competitive Advantages

- Cross-Functional Integration: Engineering, maintenance, and operations collaborate to design scalable automation solutions

- Vertical Process Automation: Automation applied from raw material through final inspection

- Data-Driven Decisions: Operational metrics feed back into process optimization and capital planning

- Customer Alignment: Systems configured to support traceability, PPAP requirements, and real-time visibility for OEMs and Tier 1 partners

Key Features

- Intelligent Automation Architecture

- Smart Manufacturing Systems (MES, SCADA)

- Robotic Cells & CNC Integration

- Error-Proofing (Poka-Yoke)

- Predictive Maintenance

- Data-Driven Process Optimization

Related Capabilities

Machining

Our automated systems often integrate with precision machining for enhanced efficiency.

Learn MoreSypris Development Center

Our design team develops innovative automation solutions tailored to specific manufacturing challenges.

Learn MoreDiscuss Your Automation Needs

Our automation specialists can help you identify opportunities to enhance your manufacturing processes through smart automation.

Contact Our Team